Events

IEEE Cement Conference

IEEE Cement Conference

April 28 - May 2, 2024

Colorado Convention Center

Denver, Colorado

AISTech 2024

AISTech 2024

May 6-8, 2024

Greater Columbus Convention Center

Columbus, Ohio, USA

News

- Webinar: Drift-free Gas Monitoring in Power Plants 14.02.2023

- Join our Webinar about "Mastering Mill dynamics in biomass fired power stations" 22.03.2022

- PROMECON promotes further education for its employees. 10.03.2022

- McON Air Compact use and benefits for other industries 28.02.2022

- Benefits of infrared system in the steel & smelters industry 24.01.2022

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

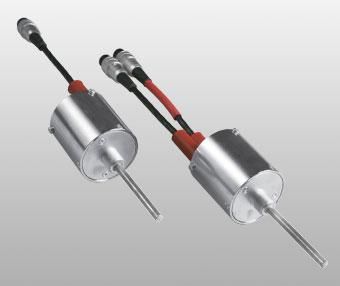

McON Air Compact McON IR

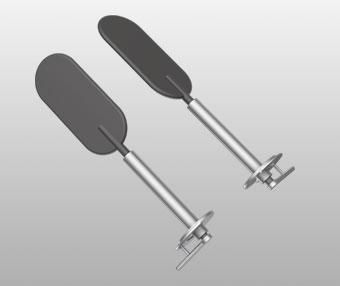

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal