International expertise

Challenging Applications

Cement making is a power consuming business. The clay, limestone and sand as main raw materials have to be crushed, ground and dried. Modern plants operate with more sensitive machinery and the process is often operated ‘on the edge’.

Modern automated processing technology and the need for a most energy efficient plant operation raises the need for accurate and reliable process control instrumentation.

The main cement making process - grinding and pyro-process - incorporates the need of precise handling of hot and dust laden air flows. Measurement of these air flows is one of the core competencies of PROMECONs MECONTROL Air and McON air system.

Internationally accepted

Leading cement manufacturers and suppliers such as CEMEX, CRH, HeidelbergCement, HOLCIM, Lafarge, LEHIGH or OEM’s like LOESCHE, FLSmidth, ThyssenKrupp or CBMI trust in PROMECON’s technology.

CEMEX ordered 4 sets of McON air to measure the tertiary air flow and exhaust gas flow in both of their two gas flow strings .

For more than seven years the downcomer sensors have been in operation with no maintenance at all.

Germany

Cemex made the Ruedersdorf cement plant more economical, increased the throughput and drastically improved the environmental aspect. PROMECON supplied drift free and low maintenance flowmeter solutions to deliver substantial process information in order to improve thermal plant efficiency by maintaining full plant availability.

CEMEX ordered 4 sets of McON air to measure the tertiary air flow and exhaust gas flow in both of their two gas flow strings .

For more than seven years the downcomer sensors have been in operation with no maintenance at all.

India

Two Indian cement production plants of Shree Cement India have been optimized utilizing PROMECON’s MECONTROL Air system during an energy conservation project conducted by Bureau of Energy Efficiency BEE and the German Technical Cooperation GTZ. Twelve and fifteen measurement points for air flow have been installed at all significant locations of the two plants.

USA

The PROMECON gas volume measurement is now installed in 6 Holcim US plants including the plant Ste. Genevieve with the largest cement kiln in the world.

The plant Devil’s Slide in Morgan UT is one of the latest who ordered the McON air gas flow measurement to measure the kiln off gas amount at the down comer duct. The benefit achieved in other plants is a smoother kiln ID fan control which results in a stabilized kiln operation. The maintenance, drift and calibration free measurement of gas velocity or gas volume with dust loads up to 20 kg/m³ and gas temperatures of up to 1000°C is now installed in 20 cement plants only on the American continent.

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

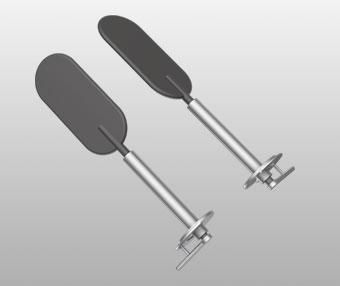

Density Damper McON Air SIL

McON Air SIL McON Temp

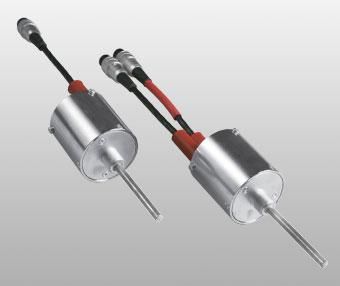

McON Temp MECONTROL Coal

MECONTROL Coal