PROMECON Downcomer gas flow measurement at Argos Newberry

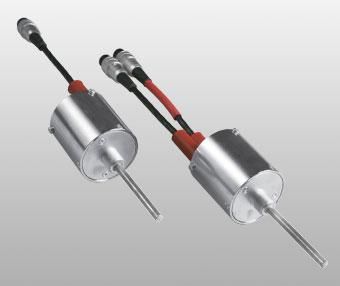

The Argos Newberry plant in Florida is operating the McON air gas flow measurement system for measuring their kiln off gas amount in the downcomer duct. The system has been developed by PROMECON GmbH in Germany.

The benefit achieved by the McON air system in this application is a smoother kiln ID fan control which results in a stabilized kiln operation. This has been successfully achieved in other cement plants.

Newberry plant operartions will sometimes cause the flow signal to go from steady to slightly uneven. This was initially questioned, but the plant is now correlating this with calciner temperature variation. So they are working to stabilize the fuel flow rates into the calciner.

Having the ability to measure on-line in these hot dusty gas streams has opened up new ways to monitor and control the cement making process.

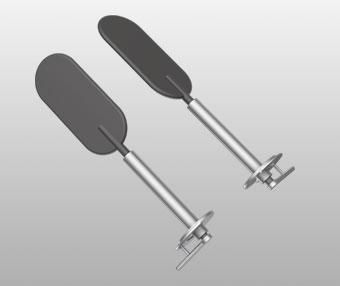

The system ist maintenance, drift and calibration free. It can be installed up to 1000°C. To date more than 100 cement plants have installed systems and up to 18 measurements at one plant. Any vertical roller mill is a good candidate for more precise flow control and fan power reduction.

- Created on .

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal