Application of measuring gas flow in the downcomer

Introduction

For the proper operation of equipment in a cement plant, knowing the flow rate is essential. In the past, high temperature and particulate in the gas stream have prevented online gas flow measurement. But the PROMECON Air Flow System utilizes the particulate to measure the velocity of the gas stream. Since the first installation at a cement plant in 2001, the system has been installed in more than 75 plants worldwide. The direct measurement of dust-carrying gas flows has opened new ways to monitor, control, and optimize the cement making process.

Measurement Technology

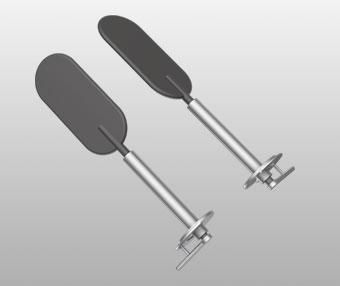

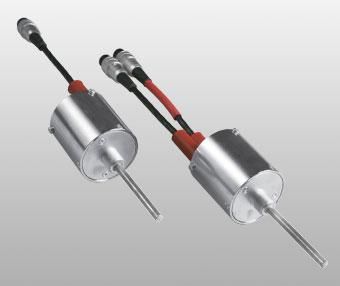

The system applies the triboelectric principle. Electrical signals created by the dust particle clouds passing each of the upstream/downstream sensors are cross correlated and referenced by their time shift. With the time of flight between the two sensors and a fixed distance (usually 350 mm), the actual particle velocity is known. For small particles, zero particle slip is assumed. The digital system requires no calibration, imparts no pressure drop, and does not drift over time.

A measurement point requires the installation of a pair of sensors aligned parallel to the longitudinal axis of the pipe. Using the cross sectional area of the pipe, as well as the pressure and temperature of the stream, the volume and mass flow can be calculated. Note that the only real measurement is time and that the measurement itself is not affected by temperature or pressure conditions of the stream.

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal