DOOSAN uses PROMECON McON air systems for new MPX plants in Brazil

The new power boilers in Pecem as well as Itaqui were recently erected and are being commissioned by DOOSAN.

In Pecem there are 3 units with a rating of 360 MWel. Itaqui will have one unit of 360 MWel and same make. The units are double wall fired and equipped with LowNOx combustion systems out of 4 pulverizers per unit. The LowNOx operation requires a state of the art air flow management for measuring the combustion air into the furnace.

For each unit PROMECON measures the following air flows:

- Secondary air (SA) into all windboxes

- Overfire Air (OFA) into all windboxes

- Primary air (PA) to all pulverizers

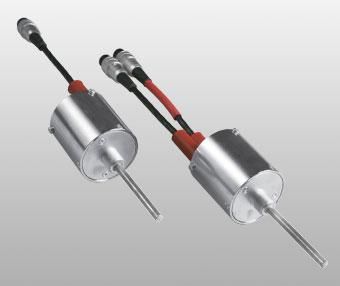

The main advantage of the PROMECON technology with correlation method and range extender is the large turndown ration of over 20. This enables the measurement of combustion air flows at full load as well as cooling air flows when burner rows are switched off. Also the drift free operation principle of the system has convinced the clients.

All measurements for combustion air and primary air are redundant and rated SIL2.

Like on all large projects PROMECON helped the client with extensive CFD simulation to find the best location for the measurement and advise on duct modifications for obtaining the best possible measurement result while mainaining:

- Lowest possible pressure drop

- Smallest possible space consumption of the ducting

By this the PROMECON systems were engineered right into the air ducting system of the new boilers.

- Created on .

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal