International expertise

Use of PROMECON's innovative measurement technology McON Air in the air volume control in a waste incineration plant - Reduction of the temperature spread above the grate by almost 50% and thus significantly optimized process control.

With the successful commissioning of the innovative air measurement technology McON Air of the PROMECON GmbH, which supports the individual regulation of the rust primary air of the line 3 of the MVA Bonn, a clear and pioneering innovation for the fire guidance at a waste incineration plant was accomplished. As a result, their temperature imbalance decreases from an average of about 200°C to about 120°C in the reference period with a significantly reduced scattering.The skew of the temperature distribution between right and left side of the grate decreases on average to about 70°C.

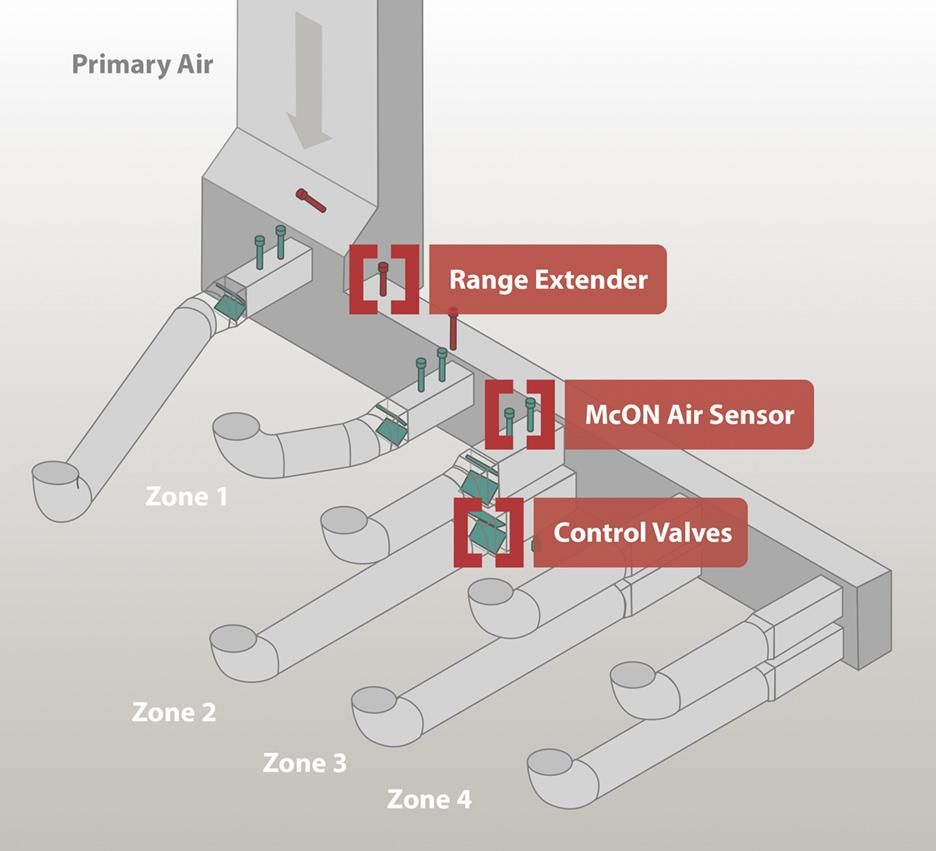

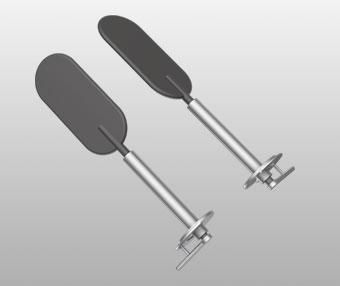

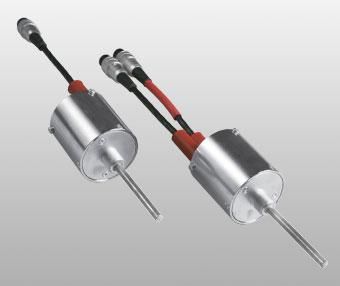

With PROMECON's McON Air air flow meter, simple retrofitting of a primary air measurement to control the individual and demand-driven air supply to the individual grate segments in waste incineration plants can be carried out. This also results in the possibility of replacing existing measurements, especially if they do not adequately meet the requirements.

The potential of the new regulatory concept has not yet been fully exploited, as the higher-level scheme for combustion is not yet adapted to the new possibilities. Further evaluation and optimization should show the full potential of the new regulation and establish it.

The PROMECON air flow measurement is suitable for many applications in dust-laden and clean air streams - even for large diameters or different geometries. In addition, the McON Air measuring system meets the operator's requirements for reliability and ease of use.

PROMECON is happy to face every new challenge and gladly supports you with ordinary and unusual challenges.

Download and read the whole scientific report here. (only German version available)

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal