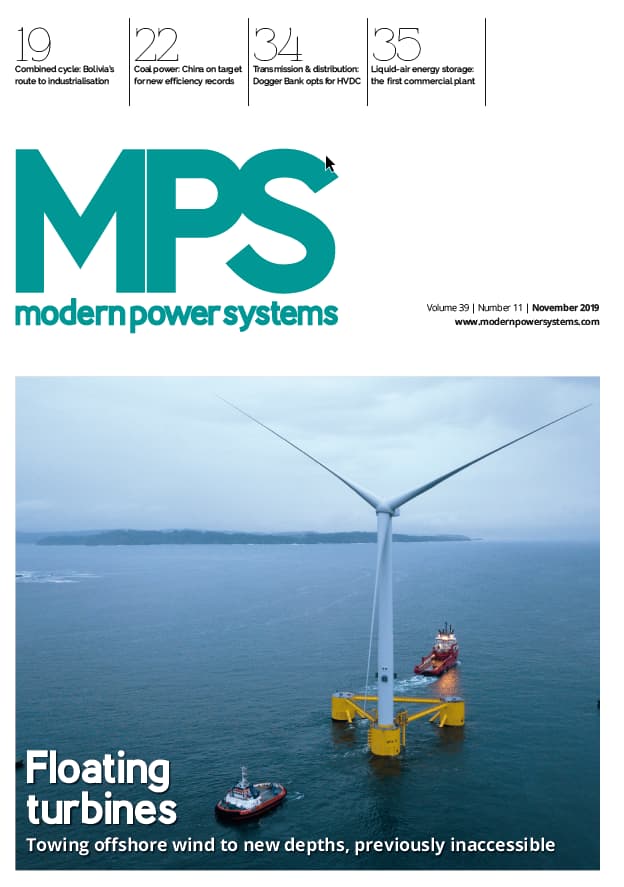

Optimisation of lignite beater wheel mills using modern gas flow measurements

A new digital time-of-flight-based cross-correlation technique, employing pairs of robust infrared sensors, enables hot recirculation gas flow into lignite beater wheel mills to be accurately measured, with significant potential benefits for mill control

Cross correlation technique The control state space in which a beater wheel mill is operated and which is defined mainly by the enthalpy flows in and out of the mill can change rather quickly if individual parameters such as the water content of the lignite is changing rapidly. In this instance the mill gas in- and output flows can undergo changes which are hard to control as the amount of heat into and out of the mill is not known.

Download the whole Article here

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal