Getting the right Balance

Hans Conrads, Promecon, outlines how new gas measurement technologies could help enable a more consistent and accurate gas flow balance in the clinker cooler, leading to a more efficient and sustainable cement making process.

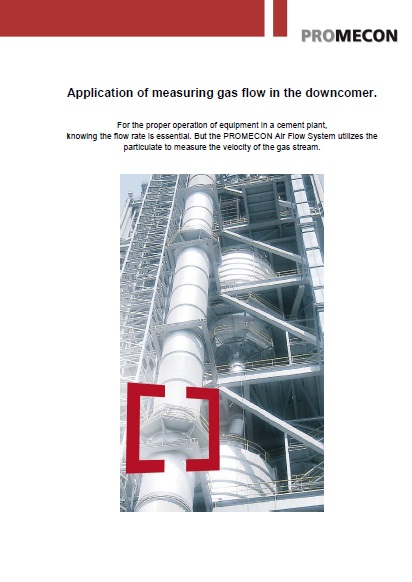

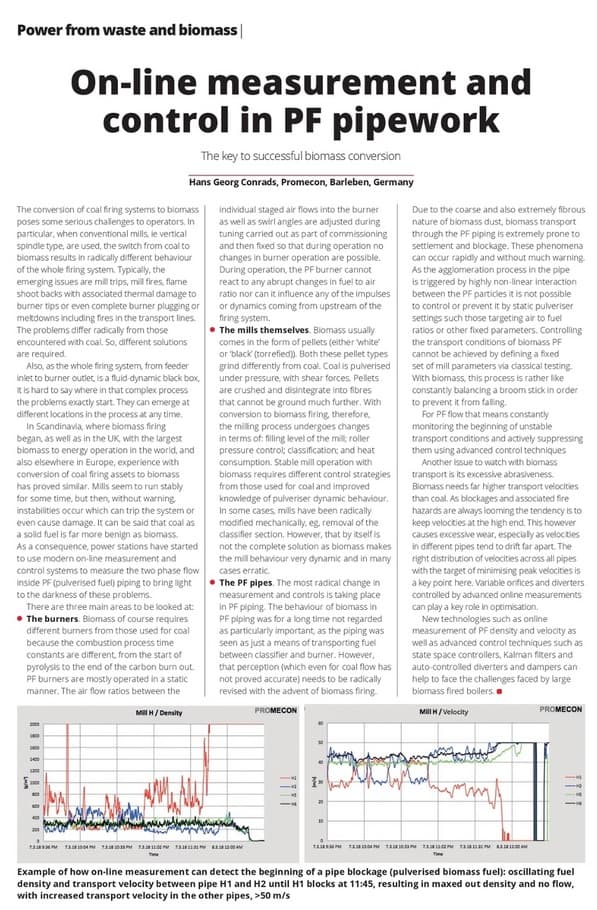

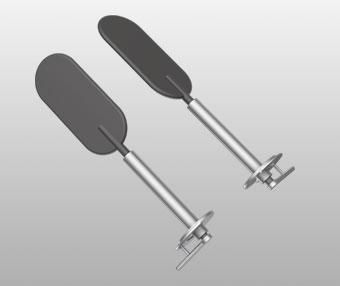

Over the past 15 years, a new measurement technology has entered the cementproducing world; this is the measurement of dusty process gas flows by cross correlation-based velocity calculation. This new technology has opened up the door for process optimisation in the pyro process, the raw milling section, as well as the finished product grinding.em utilises the triboelectric principle. Electrical signals created by (dust) particle clouds passing each of the upstream/downstream sensors are cross correlated and referenced by their time shift. The digital system requires no calibration, ...

Download the whole Article here

Energía

Energía Cemento

Cemento Acero y fundición

Acero y fundición Energía a partir de desechos

Energía a partir de desechos McON Air Compact

McON Air Compact McON IR

McON IR McON Temp

McON Temp McON Air Portable

McON Air Portable McON UBC

McON UBC MECONTROL Coal

MECONTROL Coal Regulador de densidad

Regulador de densidad McON Air SIL

McON Air SIL