Maximizing Downcomer Performance in Cement Plant Operations

From controlling airflow through the preheater tower to optimizing fan control and reducing electrical energy consumption, our sensor technology provides a comprehensive solution to the challenges of cement production.

Downcomer Optimization by PROMECON´s Gas Flow Analyzer

Reliable Downcomer Control:

Achieve superior control of your downcomer process with PROMECON’s advanced technologies. Optimization and management of airflow increases efficiency of heat recovery, enhancing energy efficiency and improving the cement production process.

Optimization of airflow through the preheater tower:

Precise downcomer airflow measurement and control allows for efficient heat recovery, resulting in improved energy efficiency.

Real Time Fan control optimization:

Control your fan in real time to optimize throughput and improve material flow, resulting in higher productivity.

Reduce electrical energy consumption:

Our advanced downcomer analysis measurement device and sensor technology enables fine-tuned control of plant components, minimizing electrical energy consumption without compromising product quality.

Rely on our sensor technology for reliable, low-maintenance and energy-efficient control of the downcomer process in cement production.

Benefits for Your Cement Plant:

- Drift-Free & Low Maintenance: Experience hassle-free operation with our drift-free system, eliminating the need for frequent calibrations or purging. Virtually maintenance-free, it reduces downtime and enhances overall plant availability.

- High Turn-Down Ratio: McON Air Compact offers a high turn-down ratio of up to 25, providing precise downcomer airflow measurement across a wide range of flow rates. This flexibility empowers precise control over your operations.

- Direct Time of Flight Measurement: Say goodbye to complex K-factors. Our analyzing system directly measures the time of flight of gas particles, ensuring highly accurate readings without the complications of traditional methods.

- Hot Tapping Solution: Minimize downtime and maximize plant availability with our hot tapping solution. Install or replace components on-the-go, ensuring uninterrupted production processes with our portable gas flow sensors.

Elevate your cement production to new heights with McON Air Compact. Experience unmatched reliability, precision, and efficiency tailored to the unique demands of the Downcomer process. Partner with us for reliable downcomer control and optimal performance in every operation.

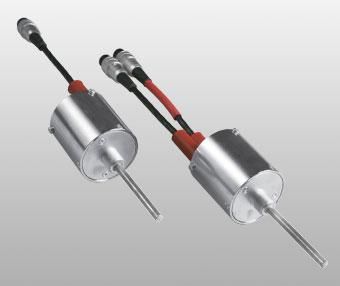

Products for Downcomer Application

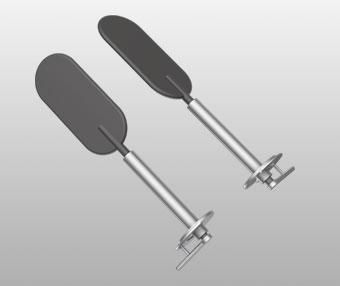

What can you expect of the flow measurement with McON Air Compact?

Optimizing Cement Production with McON Air: Reliable Flow Measurement in Extreme Conditions

Enhance your cement manufacturing process with McON Air Compact, a cutting-edge air flow measurement system meticulously designed to thrive in the demanding conditions of the Downcomer process. Our innovative solution offers precise control, reliability, and unmatched efficiency, ensuring your plant operates at peak performance.

Key Features:

1. Reliable Downcomer Control & Flow Measurement for Harsh Environments: Our Downcomer analysis measurement device, provides accurate flow measurements even in extreme conditions, handling high temperatures and dust-laden with gases even at highest dust levels up to 2500g/m³, with ease. Its robust design guarantees dependable performance, essential for controlling the Downcomer process effectively.

2. Patented Correlation Principle: Utilizing a patented correlation principle, our digital flow meter system measures the time of flight of unique signal patterns created by gas particles. This innovative approach with our patented technology, ensures accuracy and stability throughout the system's lifespan, making it an ideal choice for the challenging cement production environment.

3. Monitor your Gas Flow up to 1000 °C/1800 °F: With a remarkable temperature resistance capability, our digital flow measurement device stands up to the intense heat often experienced in the Downcomer process. This resilience ensures reliable operation in the face of extreme temperatures.

Get your offer via our contact page

Downcomer

-

Waste Heat Recovery

- Application: Control and optimize the gas and heat flow to the waste heat boiler.

- Benefits: Efficient heat recovery maximizes energy utilization, reducing environmental impact and operational costs.

-

Vertical Raw Mill

- Application: Drift and maintenance-free measurement to control the recirculation of dust-laden primary air, optimizing the grinding process.

- Benefits: Reliable measurement ensures optimal grinding efficiency, leading to improved productivity and reduced energy consumption.

-

Bypass

- Application: Precise control of bypassed gas to reduce the accumulation of pollutants in the process.

- Benefits: The controlled rejection of alkali Chlorides and sulfates enables the filtration and treatment without accumulation or too high discharge from the process.

(of Minimizing pollutants enhances environmental compliance and contributes to a cleaner, more sustainable production process.)

-

Tertiary Air

- Application: Optimizes the calcining process in cement plant through precise tertiary air measurement and control.

- Benefits: Stabilizes rotary kiln operation, reduces calciner downtime and increases the use of secondary fuels.

-

Clinker Cooler

- Application: Detailed control of each cooler stage and balance of the rotary kiln combustion air, integrated with TAD and exhaust measurement.

- Benefits: Enhanced control leads to improved clinker quality and reduced energy wastage, ensuring optimal cooler performance.

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

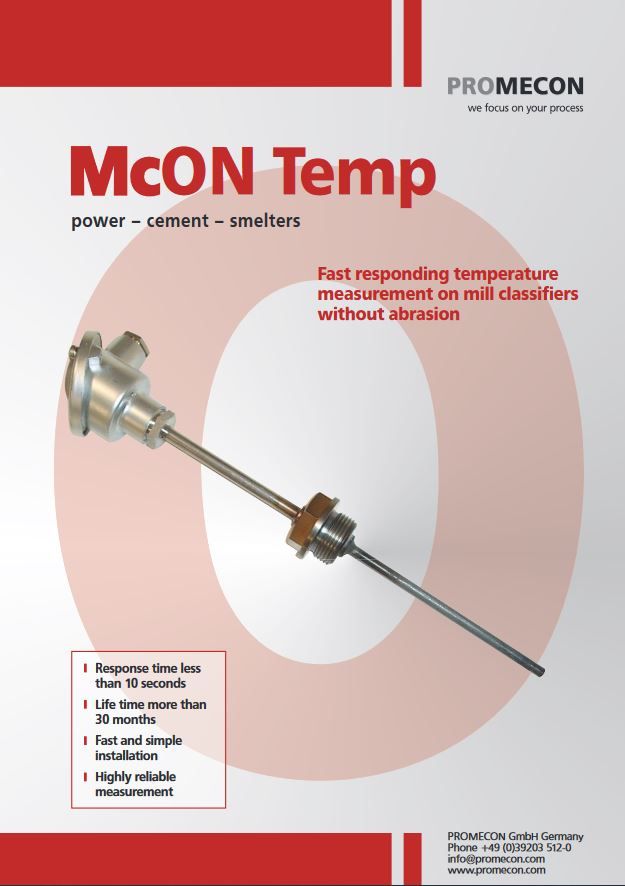

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal