Unique Tertiary Air Measurement and Control

Explore PROMECON's groundbreaking solutions for measuring and controlling tertiary air in separate line calciners (SLC). Our innovative technologies are designed to revolutionize your cement production.

Elevating Cement Plant Efficiency by PROMECON´s Gas Flow Analyzer

Precision Measurement and Control:With sensor-based tertiary air measurement and monitoring, you gain control over tertiary air supply. Our systems enable precise measurement and control, stabilizing rotary kiln operation and ensuring consistent production.

Reduced Downtime: By monitoring and controlling the calciner effectively, we minimize downtime. Our gas flow analyzer helps you identify potential issues in advance, allowing proactive interventions to prevent production interruptions.

Enhanced Use of Alternative Fuels: Precise tertiary air analysis facilitates the efficient use of alternative fuels. By optimizing tertiary air, we promote sustainable practices in your cement production, contributing to reduced operational costs.

By optimizing tertiary air in cement plants, you're on the path to a more efficient, sustainable, and profitable cement production. Contact us today to discover how our unique solutions can enhance your company's success!

Benefits for Your Cement Plant

-

Enhanced Operational Stability: Achieve consistent and stable operations with our tertiary air duct measurement device, ensuring reliable production and minimizing variations in product quality.

-

Proactive Maintenance: Identify calciner issues before they escalate, enabled by our patented digital gas flow meter, allowing timely maintenance interventions and reducing costly downtimes.

-

Sustainable Production: Increase the use of alternative fuels, promoting environmental responsibility while optimizing costs and maintaining operational efficiency, all made possible by gas flow meter working principle.

-

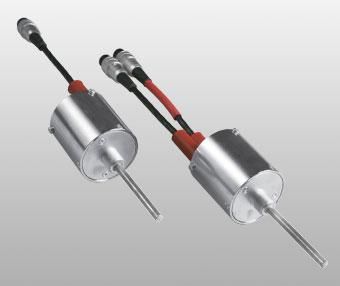

Industry-Leading Innovation:Rely on our patented technology, McON Air Compact, the result of extensive research and development. It outpaces competitors and keeps your cement plant ahead in the market.

Elevate your cement plant's performance to unprecedented levels with our tertiary air flow measurement and control system. Experience unmatched precision, operational stability, and sustainability in every aspect of your production process.

Products for Tertiary Air Application

Optimizing Cement Plant Efficiency with McON Air Compact Tertiary Air Measurement and Control

Unlock unparalleled efficiency in your cement production process with our state-of-the-art Tertiary Air Measurement and Control system. Designed specifically for monitoring and managing the tertiary air supply to the separate line calciner, this groundbreaking solution revolutionizes your operations.

Key Features:

1. Stabilizing Rotary Kiln Operation

Our advanced flow measurement system delivers precise readings of tertiary air, allowing operators to fine-tune ID fans for a steadier kiln. Since VFD-driven fans draw power proportional to the cube of the flow rate, even minor air offsets can cause a sharp rise in energy use. With reliable flow data, you maintain constant production efficiency, avoid energy spikes and reduce overall power costs.

2. Minimizing Calciner Downtime: By monitoring the calciner in real time, you catch anomalies as they occur, enabling proactive maintenance and preventing unscheduled shutdowns. Precise air-flow control protects your equipment from backflow, temperature surges, material deposits and abrasion – so you keep the line running smoothly.

3. Maximizing alternative fuel use: With accurate tertiary air measurement you achieve the optimal air-to-fuel ratio, making full use of your alternative fuels. That not only cuts your environmental footprint but also boosts cost efficiency and drives sustainable production.

4. Lower NOₓ emission, lower ammonia – measurable impact for plant and planet: Excess tertiary air in the calciner increases local oxygen levels, intensifying NOₓ formation in hot zones. By measuring and minimizing that excess precisely, operators can cut NOₓ emissions right at the source – often by 50% or more. This reduces the need for ammonia in SNCR or SCR systems, bringing down both reagent costs and the plant’s carbon footprint, given the high energy input required for NH₃ production. In short: smarter air management pays off, both ecologically and economically.

5. A Unique Measurement Solution – Where Others Fail, We Begin

Our non-intrusive, drift-free digital system is the only one of its kind on the market. Its innovative infrared approach to tertiary air measurement and control delivers precise, reliable results – even in highly abrasive and hot environments where conventional technologies reach their limits. We deliver accuracy where others give up.

Get your offer via our contact page

Tertiary Air

-

Waste Heat Recovery

- Application: Control and optimize the gas and heat flow to the waste heat boiler.

- Benefits: Efficient heat recovery maximizes energy utilization, reducing environmental impact and operational costs.

-

Vertical Raw Mill

- Application: Drift and maintenance-free measurement to control the recirculation of dust-laden primary air, optimizing the grinding process.

- Benefits: Reliable measurement ensures optimal grinding efficiency, leading to improved productivity and reduced energy consumption.

-

Bypass

- Application: Precise control of bypassed gas to reduce the accumulation of pollutants in the process.

- Benefits: The controlled rejection of alkali Chlorides and sulfates enables the filtration and treatment without accumulation or too high discharge from the process.

(of Minimizing pollutants enhances environmental compliance and contributes to a cleaner, more sustainable production process.)

-

Tertiary Air

- Application: Optimizes the calcining process in cement plant through precise tertiary air measurement and control.

- Benefits: Stabilizes rotary kiln operation, reduces calciner downtime and increases the use of secondary fuels.

-

Clinker Cooler

- Application: Detailed control of each cooler stage and balance of the rotary kiln combustion air, integrated with TAD and exhaust measurement.

- Benefits: Enhanced control leads to improved clinker quality and reduced energy wastage, ensuring optimal cooler performance.

Downloads

Discover a wealth of resources in the download section of our website, including case studies, articles from trade journals and detailed information. Here you will find in-depth insights, practical analyses and detailed explanations of our topics. Immerse yourself and benefit from first-class specialist knowledge.

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal