Redefining Vertical Raw Mill Efficiency with Advanced Sensor Technology

The Vertical Raw Mill (VRM) is a pivotal component in the grinding process within a cement plant. Efficient control and optimization of this process are critical for the quality of the end product as well as the overall efficiency and profitability of the plant.

Sensor Technology for Vertical Raw Mill Optimization

1. Optimization of the Grinding Process:

- VRM gas flow measurement allows for precise regulation of the recirculation of dust-laden primary air.

- Accurate control optimizes the grinding process, resulting in finer grinding and improved quality of the end product.

2. Efficient Energy Usage:

- VRM gas flow measurement contributes to the efficient use of energy.

- Precise monitoring and control of gas flows optimize energy consumption, leading to cost savings.

3. Prevention of Downtime:

- Drift-free and low-maintenance sensors ensure reliable and continuous measurement.

- Avoiding drift and minimizing maintenance requirements reduces downtime, contributing to uninterrupted production.

4. Quality Assurance:

- Precise measurements at the VRM help ensure the consistency and quality of the produced cement.

- Accurate control of process parameters is crucial for meeting quality standards.

5. Environmental Stewardship:

- Efficient sensor technology at the VRM can help minimize the ecological footprint of the plant.

- Vertical Raw Mill optimization process parameters can reduce resource consumption, contributing to the sustainability of operations.

Why PROMECON Sensor Technology?

Innovative Solutions: Our sensor technology offers advanced solutions tailored to the specific requirements of the VRM.

Experience and Expertise: With years of experience, we understand the industry's challenges and provide proven solutions.

Customizable Solutions: Our sensors can be tailored to the individual needs of your plant.

Sustainability: Our technologies help to increase mill recirculation gas flow, efficiency, and conserve resources.

Contact us for a detailed consultation on our sensor technology at the VRM

Products for Vertical Raw Mill Application

Significance of Sensors in Air and Gas Measurement in Vertical Raw Mills

The application of precise sensor technology, exemplified by the McON Air Compact Flow Measurement System, in air and gas measurement at the Vertical Raw Mill in a cement plant is crucial for optimizing the milling process and enhancing overall plant efficiency.

-

Precision Control of Primary Air Circulation: High-Tech Sensors precise measurement of dust-laden primary air enables constant and accurate control of primary air circulation. This is critical for fine-tuning the milling process and optimizing production performance.

-

Drift-Free Operation: The system's drift-free operation ensures continuous and reliable measurement over an extended period without the need for repeated calibrations. This is particularly important for consistent control in the dynamic environment of a Vertical Raw Mill.

-

Temperature Resistance up to 1000 °C/1800 °F: The ability to withstand high temperatures in a Vertical Raw Mill allows for accurate measurement and control under extreme conditions. Optimized mill recirculation gas flow significantly contributes to the efficiency of the milling process.

-

Maintenance-Free Operation for Continuous Production: McON Air Compact's maintenance-free operation minimizes downtime, as it can operate continuously. This is crucial for uninterrupted production and efficient milling operations.

The integration of advanced sensor technology into air and gas measurement in the Vertical Raw Mill not only promotes environmental compatibility but also enhances process stability and energy efficiency in cement production.

Get your offer via our contact page

Vertical Raw Mill

-

Waste Heat Recovery

- Application: Control and optimize the gas and heat flow to the waste heat boiler.

- Benefits: Efficient heat recovery maximizes energy utilization, reducing environmental impact and operational costs.

-

Vertical Raw Mill

- Application: Drift and maintenance-free measurement to control the recirculation of dust-laden primary air, optimizing the grinding process.

- Benefits: Reliable measurement ensures optimal grinding efficiency, leading to improved productivity and reduced energy consumption.

-

Bypass

- Application: Precise control of bypassed gas to reduce the accumulation of pollutants in the process.

- Benefits: The controlled rejection of alkali Chlorides and sulfates enables the filtration and treatment without accumulation or too high discharge from the process.

(of Minimizing pollutants enhances environmental compliance and contributes to a cleaner, more sustainable production process.)

-

Tertiary Air

- Application: Optimizes the calcining process in cement plant through precise tertiary air measurement and control.

- Benefits: Stabilizes rotary kiln operation, reduces calciner downtime and increases the use of secondary fuels.

-

Clinker Cooler

- Application: Detailed control of each cooler stage and balance of the rotary kiln combustion air, integrated with TAD and exhaust measurement.

- Benefits: Enhanced control leads to improved clinker quality and reduced energy wastage, ensuring optimal cooler performance.

Downloads

Discover a wealth of resources in the download section of our website, including case studies, articles from trade journals and detailed information. Here you will find in-depth insights, practical analyses and detailed explanations of our topics. Immerse yourself and benefit from first-class specialist knowledge.

Power

Power Steel & Smelters

Steel & Smelters Cement

Cement Waste to Energy

Waste to Energy McON Air Portable

McON Air Portable McON UBC

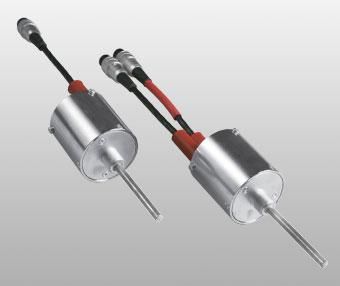

McON UBC McON Air Compact

McON Air Compact McON IR

McON IR Density Damper

Density Damper McON Air SIL

McON Air SIL McON Temp

McON Temp MECONTROL Coal

MECONTROL Coal